Natural

Sheep Casings

Double-click to edit text, or drag to move.

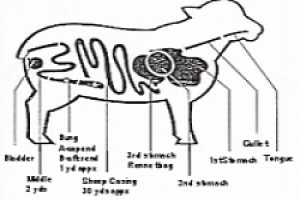

THE PRODUCT

Sheep casings for natural sausage skins are made from the small intestine which measures approx. 30 yards in length.

The total length of the small intestine is referred to as either the 'runner' or a 'set'.

The calibre (diameter) of natural sheep casings can range from 16 mm up to 28 mm and when calibrated are

offered in sizes of 2 mm increments e.g. 16/18 mm, 18/20 mm, 20/22 mm etc.

THE SAUSAGES

Sheep casings are used to make the following types of sausage:

Chipolatas, Butcher's thin sausages, Cocktail sausages, Breakfast sausage, Frankfurters, Bockwurst, Wieners

and Chorizo.

Sausages described as 'traditional', 'premium' or 'finest' are most likely to be made with natural casings.

On packaged chipolata size sausages, made with natural casings, the ingredients will probably state " Filled into natural

sheep casings ".

CHARACTERISTICS

There are no straight lines in nature. Sheep casings are naturally coiled. Sausages made with natural sheep casings have the

traditional curved shape.

Natural casings have an inherent permeability. It is not necessary to prick sausages made with natural sheep casings.

OTHER PRODUCTS

SURGICAL SUTURES

It is thought that the use of animal intestines for surgical procedures was first used by the 10th. century surgeon al-Z ahrawi, in

Moorish Spain, who reportedly discovered the dissolving nature of 'catgut' when his lute strings were eaten by a monkey.

As indicated elsewhere in these pages, the sheep intestine narrows in size and decreases in quality from the stomach to the bung end.

The narrow end of the intestine is often referred to as 'suture material' and in some instances is

unsuitable for sausage production due to being too narrow or having numerous holes.

In simple terms, the process for producing surgical sutures is that the cleaned intestine is

'split' (cut) lengthwise to produce lengths of 'ribbons'.

After soaking in water a number of ribbons or plys would be spun together and hung, under tension, on

frames in temperature and humidity controlled rooms until dry.

The final processes would be to polish for a smooth finish, cut to length, attached to needles and

sterilised.

Natural gut sutures are mainly used for internal surgery due to its ability to 'dissolve' and be

absorbed the body over a period of time.

Most natural gut surgical sutures these days are produced from beef serosa (see Natural Beef Casings) which is cheaper to produce

and more readily available than sheep suture material.

RACKET STRINGS

So called suture material was, for some reason, more prevalent in sheep in Australia which became

one of the main producers of natural gut tennis strings.

Up until the advent of the large headed tennis rackets it took app. 7 ½ yards for a tennis racket.

The same narrow end material and process used in the production of sutures was used to produce

natural gut tennis strings the variation being in the number of ribbons or plys used to give a thicker string.

The use of sheep gut for the production of tennis strings died out with the popularity of large headed

rackets which required a string of 11 yards. A single length of string was required and it was impossible

to produce a string of this length without cutting in to the more valuable sausage skin material.

Again tennis string production turned to beef serosa which could easily be produced in the longer length

required.

Despite advances in synthetic material natural gut racket strings are readily available today and are

considered the best for top professionals due to the natural strength and elasticity under high tension.

MUSIC STRINGS

Catgut is not made with the gut of cats. It is thought that this term derived

from 'kitgut', a kit being a type of medieval violin strung with sheep gut.

Again, despite the advances made in synthetic materials, strings for violins,

guitars and most notably harps are still being produced from sheep intestine

and beef serosa.

The process is the same as that for sutures and racket strings. With the

number of plys varied for the particular size (guage) of string required.

Traditionally all stringed instruments had natural gut strings and they are

still considered as giving a superior performance for some instruments.

NATURAL CONDOM

The oldest condoms found (rather than just pictures or descriptions) are from 1640 discovered in Dudley Castle in England.

They were made from animal intestine.

Natural lamb condoms are produced from the caecum (bung cap).

The initial process is very simple. At the abattoir the bung caps are flushed inside

and out with water by a specially designed bung washing machine, salted, packed in

barrels and sent for further processing.

Up until the 1980's there was a huge demand from America with almost every bung

cap produced in New Zealand being sent to pharmaceutical companies there

for further processing and manufacture.

This was at a time when the annual New Zealand lamb kill was around 35 million.

Such was the demand for this product that at the start of the 1980's U.K. and Irish abattoirs were also installing bung washing

machines and exporting to America.

However, this demand dropped very sharply with an increasing awareness, around that time, of STIs (sexually transmitted infections)

and the opinion was that the natural porosity of animal intestines did not protect against STIs.

Natural lamb condoms are still being produced today in America from New Zealand lamb bung caps with the manufacturers

themselves stating that natural lamb condoms are for pregnancy protection only.